<back

How Do Custom Connector Suppliers Meet Industry-Specific Requirements?

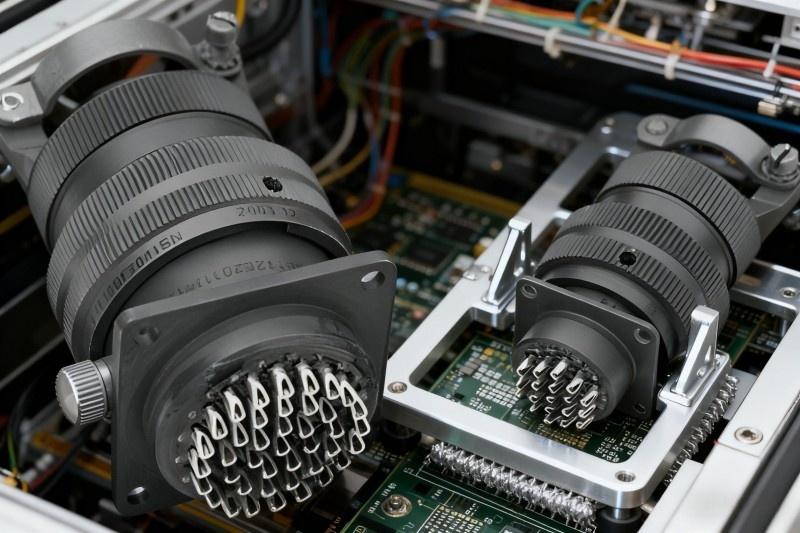

When it comes to industries that rely on intricate, high-performance electrical systems, such as automotive, telecommunications, medical devices, and aerospace, the importance of custom connectors cannot be overstated. Custom connector suppliers play a crucial role in providing solutions that meet the specific needs of these sectors. But how exactly do they ensure their connectors align with industry-specific requirements?

In this article, we will explore how connector manufacturers, connector distributors, and custom connector suppliers work closely with businesses to deliver tailored solutions that meet the unique demands of various industries.

1. Understanding Industry Standards and Compliance

Each industry has a set of standards and regulations that connectors must comply with. These include safety standards, environmental requirements, and performance criteria. For example, medical devices require connectors that meet stringent regulatory guidelines, while automotive connectors must be able to withstand high vibrations, extreme temperatures, and corrosive environments.

How Custom Connector Suppliers Address This:

Regulatory Knowledge: A connector manufacturer or connector distributor familiar with industry regulations ensures their products meet necessary certifications (e.g., ISO, UL, CE, RoHS).

Tailored Design for Compliance: Custom connector suppliers design connectors specifically to meet the performance standards of industries like aerospace, medical, or defense.

By closely understanding these standards, suppliers can create connectors that not only fit the technical specifications but also comply with the necessary legal and safety standards.

2. Providing High-Performance Solutions

Industries such as telecommunications, automotive, and military demand connectors that can function in extreme conditions, such as high heat, moisture, or pressure. These conditions can put connectors to the test, requiring a higher level of performance than what standard connectors offer.

How Custom Connector Suppliers Meet Performance Demands:

Materials Expertise: A connector manufacturer works with specialized materials like high-temperature resistant plastics, corrosion-resistant metals, and even custom alloys that can withstand environmental stressors.

Custom Design and Testing: Connector distributors and custom connector suppliers often provide prototypes and perform rigorous testing to ensure connectors meet real-world performance demands—such as durability, reliability, and electrical efficiency.

By focusing on the performance needs of specific industries, these suppliers ensure that their connectors are up to the task, whether it’s in a high-speed network or a high-powered electric vehicle.

3. Optimizing for Space and Size Constraints

In many industries, space is at a premium. For instance, aerospace applications require connectors that fit within tight spaces without compromising on performance. Medical devices often require compact, lightweight connectors that don’t add bulk but still maintain reliability. Custom connector suppliers have the expertise to provide connectors that meet size constraints while maintaining functionality.

How Custom Connector Suppliers Handle Size and Space Challenges:

Miniaturization Capabilities: Many connector manufacturers specialize in designing small, high-performance connectors that can function in highly compact environments.

Custom Solutions: Custom connector suppliers create connectors that are specifically sized and shaped to fit into unique device configurations, ensuring optimal space utilization without sacrificing power or safety.

By working closely with clients, connector distributors can source connectors that meet size specifications and help companies save space, reduce weight, and optimize overall design.

4. Ensuring Environmental Resistance

Certain industries, such as automotive, military, and marine, require connectors that can resist environmental challenges like water, dust, high pressure, and temperature fluctuations. For example, automotive connectors must withstand the harsh conditions under a vehicle’s hood, while marine connectors are designed to operate in high-moisture environments.

How Custom Connector Suppliers Tackle Environmental Challenges:

Sealing Technologies: A custom connector supplier often incorporates sealing technologies such as O-rings and gaskets to ensure connectors are water- and dust-proof.

Advanced Coatings: To protect connectors from corrosion or wear, connector manufacturers use specialized coatings or plating processes like gold or silver plating, which help protect the connectors from environmental degradation.

By offering environmental resistance features such as weatherproofing and corrosion protection, connector distributors ensure that connectors are not only durable but also reliable across varying conditions.

5. Customization for Unique Needs

One of the primary advantages of working with a custom connector supplier is the ability to tailor connectors to meet very specific requirements. Whether it’s for high-frequency signal transmission, low power consumption, or unique physical form factors, custom connectors allow for precise tailoring to a product’s needs.

How Custom Connector Suppliers Offer Tailored Solutions:

Bespoke Design: A connector manufacturer provides customized connectors designed to meet the exact specifications of the client’s application, from pin configurations to connector housing.

Prototyping and Iteration: Suppliers often collaborate with engineers to create prototypes and refine designs, ensuring the connector works seamlessly within the intended system.

Cross-Industry Collaboration: Connector distributors often work across industries, allowing them to apply lessons and innovations from one sector to another, providing cutting-edge, high-quality custom connectors.

This level of customization ensures that connectors can fit into a wide range of applications, from highly specialized medical equipment to next-generation vehicles and aerospace systems.

6. Providing Ongoing Support and Availability

The job of a connector manufacturer or connector distributor doesn’t end once the connectors are delivered. Many industries require ongoing support for installation, maintenance, and troubleshooting, and a reliable supplier can offer this long-term partnership.

How Custom Connector Suppliers Provide Support:

Technical Assistance: Many connector manufacturers offer technical support to help with product integration, installation, and troubleshooting.

Reliable Stock and Reordering: Connector distributors ensure that high-quality connectors are available for restocking or emergency replacements, minimizing downtime.

This continuous support ensures that businesses can rely on custom connector suppliers to keep their systems running smoothly over time.

Summary:

Custom connector suppliers play a pivotal role in industries that require specialized, high-performance connectors. From adhering to strict industry standards to offering tailored solutions, connector manufacturers and connector distributors meet the specific needs of various sectors. By providing durable, reliable, and customized connectors, they ensure that industries—from medical to aerospace—can operate efficiently and safely. Whether it's for enhanced performance, environmental resistance, or space optimization, working with a trusted custom connector supplier ensures that your systems are equipped with the best connectors for the job.