<back

Can a Custom-Matched Connector Solution Reduce Downtime and Failures?

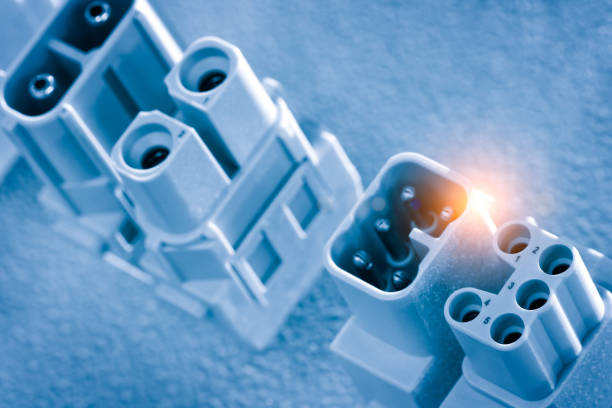

In high-performance industrial environments—where even seconds of downtime can result in thousands of dollars in losses—system reliability is paramount. One often-overlooked component in the reliability equation is the electrical connector. While off-the-shelf connectors are widely available, they are not always optimized for specific applications. That’s where a custom-matched connector solution can make all the difference.

But can such a tailored connector solution truly reduce downtime and prevent system failures? The short answer is yes—and in this article, we’ll explore why.

What Is a Custom-Matched Connector Solution?

A custom-matched connector solution is not just a connector—it’s an engineered interface designed specifically for your application’s mechanical, electrical, and environmental needs. These connectors are:

Matched to your operating voltage/current

Compatible with unique form factors

Optimized for vibration, heat, moisture, or EMI environments

Designed for easy installation and low maintenance

Rather than fitting your system around a generic connector, a custom-matched design ensures the connector fits perfectly within your system architecture—improving efficiency, durability, and long-term reliability.

Why Standard Connectors Often Fail

Many manufacturers still rely on standard connectors because they’re easy to procure and seem cost-effective. However, mismatches between connector specifications and application demands often lead to:

Frequent disconnections

Corrosion or water ingress

Overheating and arcing

Mechanical damage from vibrations

EMI signal degradation

These seemingly minor failures can snowball into major system outages, especially in mission-critical sectors such as aerospace, rail transit, defense systems, or marine engineering.

This is where custom connector solutions come into play—eliminating mismatches and engineering vulnerabilities at the design level.

How Custom-Matched Connector Solutions Reduce Downtime

1. Tailored to Environmental Conditions

Custom connectors are designed with specific operating environments in mind. Whether your system operates in extreme temperatures, is submerged in saltwater, or exposed to dust and chemicals, a tailored connector solution offers:

IP67/IP68 sealing for waterproofing

Anti-corrosion coatings for marine or chemical exposure

Vibration-resistant locking mechanisms for transportation and military use

Heat-resistant materials for high-temperature environments

These features ensure your connector system remains stable and safe, even in the harshest conditions—directly reducing the risk of failure.

2. Optimized Electrical Performance

Custom-matched connectors are engineered to match voltage, current, and impedance requirements. Overloaded or mismatched standard connectors can lead to arcing, signal loss, or even short-circuits. A reliable custom connector solution prevents such failures by:

Using the correct number and gauge of contacts

Minimizing signal loss in high-frequency applications

Integrating EMI/RFI shielding for signal integrity

Ensuring precise mating and contact pressure

These performance gains minimize the risk of electrical faults, improving connector reliability over time.

3. Easier Maintenance and Installation

Downtime often results not from the connector failure itself—but from the time needed to locate, access, and replace the faulty component. Custom-matched connector solutions can be designed for:

Tool-free installation

Quick-release locking mechanisms

Color-coded or key-aligned interfaces

Modular designs for hot-swapping

This reduces Mean Time to Repair (MTTR) and ensures your maintenance team can act swiftly—reducing unplanned system outages.

4. Lower Replacement Rates

Since custom connectors are engineered for longer life cycles, their components typically last significantly longer than standard options. This reduces the frequency of:

Inspections

Component swaps

Emergency service calls

Inventory stocking costs

Fewer interruptions mean lower operational downtime and more consistent system performance.

Which Industries Benefit the Most?

Custom connector solutions are not a luxury—they’re a necessity in industries where performance and safety are non-negotiable:

| Industry | Why Custom Connectors Matter |

|---|---|

| Aerospace & Defense | Need for shock resistance, EMI shielding, and space-grade materials |

| Rail Transit | Vibration-proof, waterproof, long life cycle under constant motion |

| Marine & Offshore | Corrosion-resistant and watertight for harsh sea environments |

| Energy Sector | High voltage, thermal endurance, explosion-proof capabilities |

| Medical Equipment | Precise signal transmission, biocompatibility, small form factors |

| Industrial Automation | Fast connections, rugged housing, easy integration with control systems |

By using custom connector solutions, these sectors not only reduce the likelihood of failures but also enhance overall system safety and compliance.

Case Example: Reducing Failures in Rail Transit

Let’s take railway signaling systems as an example. Enzhuer, a leading industrial connector manufacturer, provided a custom-matched connector solution for a metro operator experiencing intermittent signal failures due to vibration-induced disconnections.

By replacing the standard connector with a custom vibration-proof locking system, and using IP68 sealed connectors, the operator saw:

Zero failures in 12 months

30% reduction in overall maintenance time

Improved system safety compliance

This showcases the tangible value of investing in reliable connector systems that are built specifically for the application.

Choosing the Right Connector Partner

Creating a successful custom-matched connector solution requires a manufacturer with deep industry knowledge and engineering capability. A trusted partner like Enzhuer offers:

Over 20 years of experience in custom connector design

Serving sectors like military, shipbuilding, automation, and aerospace

Full-service capabilities: prototyping, testing, production, certification

Rapid support and global delivery

A custom solution is only as good as the team behind it—so ensure your connector manufacturer offers real engineering collaboration, not just catalog parts.

Questions to Ask Before Adopting a Custom Connector Solution

Before upgrading to a custom-matched system, consider the following:

What are the exact electrical, mechanical, and environmental needs of my application?

Are standard connectors causing frequent failures or service interruptions?

Can custom connectors be designed to integrate with my current hardware?

Will a custom solution reduce long-term maintenance and operating costs?

What compliance or certification standards must be met?

These questions will help you evaluate if a custom connector solution is a strategic investment—not just a technical adjustment.

Conclusion: Fewer Failures, More Uptime

So—can a custom-matched connector solution reduce downtime and failures? Absolutely.

By aligning perfectly with the needs of your application, custom connectors reduce the root causes of many common failures—from environmental degradation to signal interference. They also enable easier maintenance, better reliability, and longer product life cycles.

In high-stakes industries, these benefits are more than just convenient—they’re critical.

Whether you're dealing with complex industrial systems or building the next generation of transportation or defense technologies, a custom connector solution from a trusted manufacturer like Enzhuer can provide the durability, precision, and dependability your system demands.